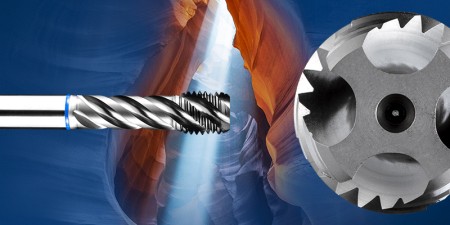

High Speed Steel (HSS) provides good wear resistance and costs less than cobalt or carbide end mills. HSS is used for general-purpose milling of both ferrous and nonferrous materials. It is a cost-effective material ideal for machining cast iron, steel and titanium alloys.

HSS, 2 FLUTE END MILLS-REGULAR LENGTH

HSS, 2 FLUTE END MILLS-LONG LENGTH

HSS, 2 FLUTE END MILLS-EXTENDED LENGTH

HSS, 2 FLUTE DOUBLE END MILLS-REGULAR LENGTH

HSS, 2 FLUTE BALL NOSE END MILLS-REGULAR LENGTH

HSS, 2 FLUTE BALL NOSE END MILLS-EXTENDED LENGTH

HSS, 2 FLUTE DOUBLE BALL NOSE END MILLS-REGULAR LENGTH

HSS, 4 FLUTE END MILLS-REGULAR LENGTH

HSS, 6 FLUTE END MILLS-REGULAR LENGTH

HSS, 4&6 FLUTE END MILLS-LONG LENGTH

HSS, 4&6 FLUTE END MILLS-EXTRA LONG LENGTH

HSS, 4 FLUTE DOUBLE END MILLS-REGULAR LENGTH

HSS, 4 FLUTE END MILLS-REGULAR LENGTH(CENTER CUTTING)

HSS, 6 FLUTE END MILLS-REGULAR LENGTH(CENTER CUTTING)

HSS, MULTI FLUTE END MILLS-MEDIUM LENGTH(CENTER CUTTING)

HSS, 4&6 FLUTE END MILLS-LONG LENGTH(CENTER CUTTING)

HSS, 4&6 FLUTE END MILLS-EXTRA LONG LENGTH(CENTER CUTTING)

HSS, 4 FLUTE DOUBLE END MILLS-REGULAR LENGTH(CENTER CUTTING)

HSS, 6 FLUTE DOUBLE END MILLS-SINGLE END with COMBINATION 2(CENTER CUTTING)

HSS, 2 FLUTE MINIATURE DOUBLE END MILLS-STUB LENGTH