Description

CBN series

| Grade | Style | Coating | Main Binder | CBN Volume | Applications | ||||

|---|---|---|---|---|---|---|---|---|---|

| Cast Iron | Ductile Cast Iron |

Hardened Material |

Mill Rolls | Sintered Alloy |

|||||

| B99 | Solid | – | AlN | 93% | ● | ○ | ● | ||

| B23 | Brazed | – | Ti | 90% | ● | ● | |||

| B30 | Brazed | – | Ti | 95% | ● | ● | |||

| B36 | Brazed | – | TiCN | 65% | ● | ||||

| B6K | Brazed | TiCN | TiCN | 65% | ● | ||||

| B40 | Brazed | – | TiN | 65% | ● | ||||

| B52 | Brazed | – | TiC | 50% | ● | ● | |||

| B5K | Brazed | TiCN | TiC | 50% | ● | ● | |||

B99

Features

- Excellent wear resistance for high-speed cast iron machining

- Ideal for Mill-roll machining

[ Recommended cutting conditions ]

| Work material | Application | Purpose | Cutting speed (SFM) | Feed (IPR) |

Depth of cut (inch) | DRY | WET |

|---|---|---|---|---|---|---|---|

| Cast iron | Turning | Rough Semi finish |

2000-4500 | .006-.020 | .020-.140 | ● | ● |

| Mill Rolls | Turning | Rough Semi finish |

100-200 | .004-.012 | .010 | ● |

B23

Features

- Excellent wear resistance thanks to high CBN content

- Ideal for roughing cast iron and machining sintered materials

| Brake rotor | |

|---|---|

| Gray cast iron | |

| 820 SFM | |

| .0079 IPR | |

| .079″ DOC | |

| WET | |

| NTK : B23 | 210 pcs |

| Competitor’s CBN | 70 pcs |

[ Recommended cutting conditions ]

| Work material | Application | Purpose | Cutting speed (SFM) | Feed (IPR) |

Depth of cut (inch) | DRY | WET |

|---|---|---|---|---|---|---|---|

| Cast iron | Turning | Rough Semi finish |

1300-4500 | .004-.020 | .008-.080 | ○ | ● |

| Sintered alloy | Turning | Rough – Finish | 150-750 | .001-.008 | .002-.020 | ● | ● |

B30

Features

- Excellent wear resistance thanks to high CBN content

- Designed for finishing cast iron

| Cylinder block | |

|---|---|

| Cast iron | |

| 2600 SFM | |

| .012 IPR | |

| .004″ DOC | |

| WET | |

| NTK : B30 | 800 pcs |

| Competitor’s CBN | 500 pcs |

| Work material | Application | Purpose | Cutting speed (SFM) | Feed (IPR) |

Depth of cut (inch) | DRY | WET |

|---|---|---|---|---|---|---|---|

| Cast iron | Turning | Semi finish Finish |

1300-4500 | .004-.020 | .008-.080 | ○ | ● |

B6K / B36

Features

- Excellent combination of wear resistance and toughness due to special TiCN binders

- Best for semi-interrupted cutting of hardened materials

| Gear (HRC61-65) | |

|---|---|

| 5120H | |

| 430 SFM | |

| .006 IPR | |

| .004″ DOC | |

| DRY | |

| NTK : B36 | 50 pcs |

| Competitor’s CBN | 20 pcs |

[ Recommended cutting conditions ]

| Work material | Application | Purpose | Cutting speed (SFM) | Feed (IPR) |

Depth of cut (inch) | DRY | WET |

|---|---|---|---|---|---|---|---|

| Hardened material | Turning (Light interruption – Medium interruption) |

Rough – Finish | 130-800 | .002-.008 | .004-.040 | ● | ● |

B40

Features

- Exceptional toughness thanks to special TiN binders

- Designed for severely interrupted cutting of hardened materials

| Universal joint (HRC62) | |

|---|---|

| 1055 | |

| 360 SFM | |

| .0055 IPR | |

| .0059″ DOC | |

| DRY | |

| NTK : B40 | 2300 pcs |

| Competitor’s CBN | 1500 pcs |

[ Recommended cutting conditions ]

| Work material | Application | Purpose | Cutting speed (SFM) | Feed (IPR) |

Depth of cut (inch) | DRY | WET |

|---|---|---|---|---|---|---|---|

| Hardened material | Turning (Heavy interruption) |

Rough – Finish | 100-500 | .002-.008 | .004-.040 | ● | ○ |

B5K / B52

Features

- Excellent wear resistance due to optimum CBN content with special TiC binders

- Ideal for finishing ductile cast iron and continuous cuts for finishing hardened materials

| Hub | |

|---|---|

| Ductile cast iron | |

| 1150-1130 SFM | |

| .003 IPR | |

| .0079″ DOC | |

| WET | |

| NTK : B52 | 60 pcs |

| Competitor’s CBN | 30 pcs |

[ Recommended cutting conditions ]

| Work material | Application | Purpose | Cutting speed (SFM) | Feed (IPR) |

Depth of cut (inch) | DRY | WET |

|---|---|---|---|---|---|---|---|

| Ductile cast iron | Turning | Finish | 300-1600 | .004-.016 | .012-.080 | ○ | ● |

| Hardened material | Turning (Continuous – Light interruption) |

Rough – Finish | 300-1000 | .004-.020 | .004-.040 | ○ | ● |

PCD (Polycrystalline Diamond)

Features

- Faster cutting speeds than carbide

- Recommended for cutting aluminum and copper alloys thanks to its excellent adhesion resistance

- Incorporates a very sharp cutting edge

- Available for general turning and cut-off in addition to the inserts for milling cutters

[ Recommended cutting conditions ]

| Work material | Application | Purpose | Cutting speed (SFM) | Feed (IPR) |

Depth of cut (inch) | DRY | WET |

|---|---|---|---|---|---|---|---|

| Aluminum alloy Non-ferrous material |

Turning | Rough – Finish | – 6500 | – .006 | – .200 | ● | |

| Milling | Rough – Finish | – 25000 | – .008 | – .200 | ● |

PD1

Features

- Sharp cutting edges

- Enables high precision and stable machining by controlling the potential for built-up edge

| Spool | ||

|---|---|---|

| ①Rough | ②Finish | |

| A6061 | A6061 | |

| 660 SFM | 660 SFM | |

| .004 IPR | .002 IPR | |

| .200 DOC | .008 DOC | |

| ①NTK : PD1 | 30,000 pcs | |

| ②NTK : PD1 | 30,000 pcs | |

PD2

Features

- Super micro grain PCD maintains sharp cutting edges with increased chipping resistance

- Good chip control due to the high rake angle on the insert

- 3D Chipbreaker is now available

| Spool | |

|---|---|

| A6061 | |

| 560 SFM | |

| .002 IPR | |

| .006 DOC | |

| NTK : PD2 | 15,000 pcs |

| Competitor’s PCD | 10,000 pcs |

PCD with Laser-Chip-Breaker

PCD – Milling Cutter Insert

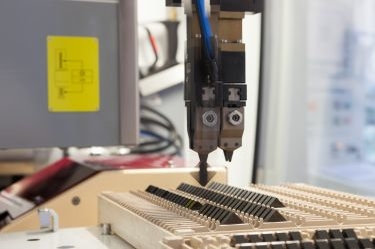

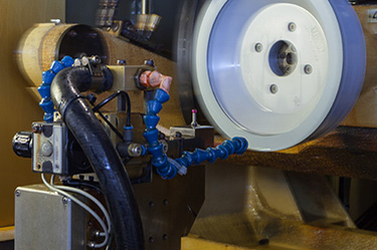

Automated Production

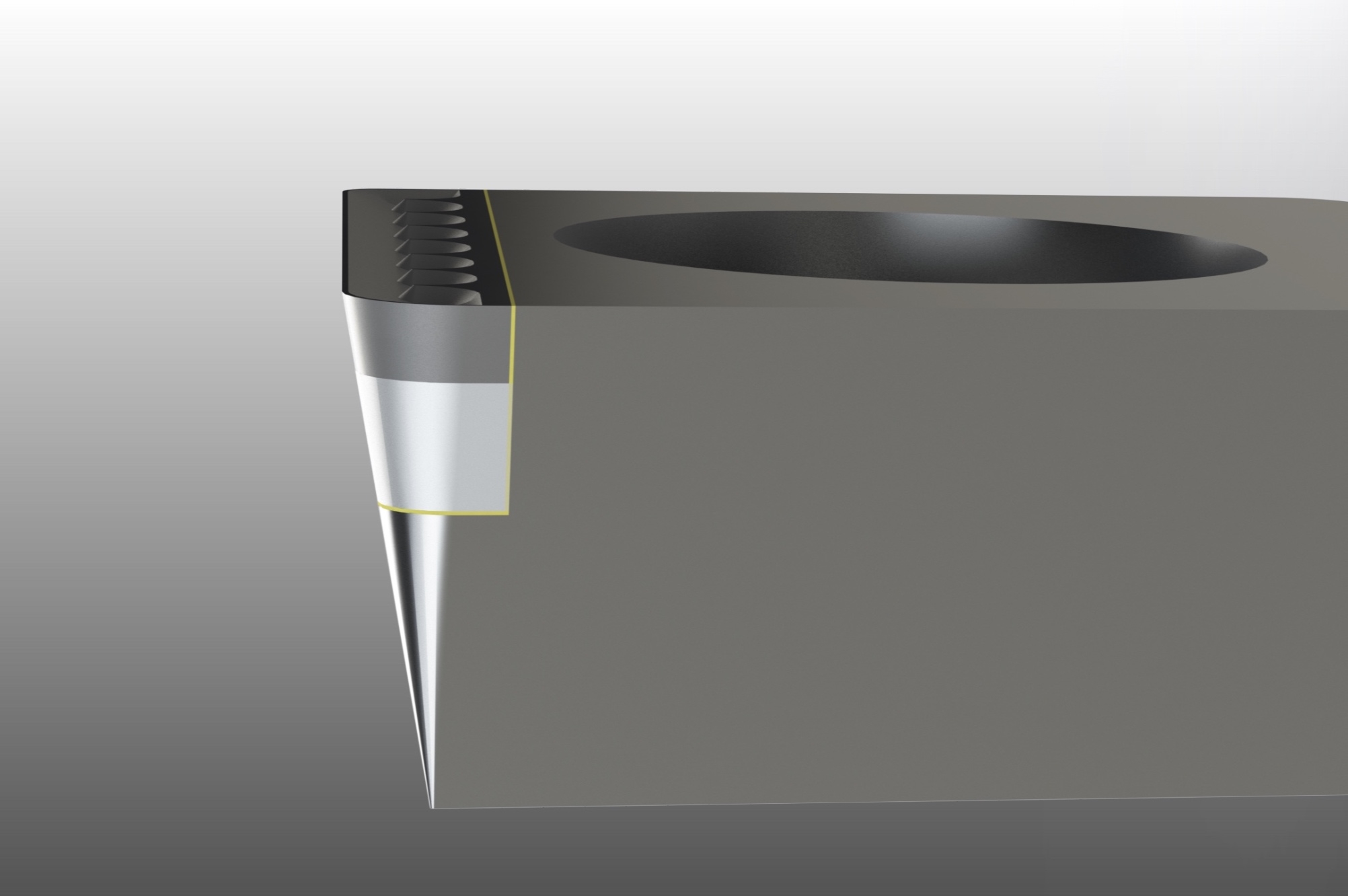

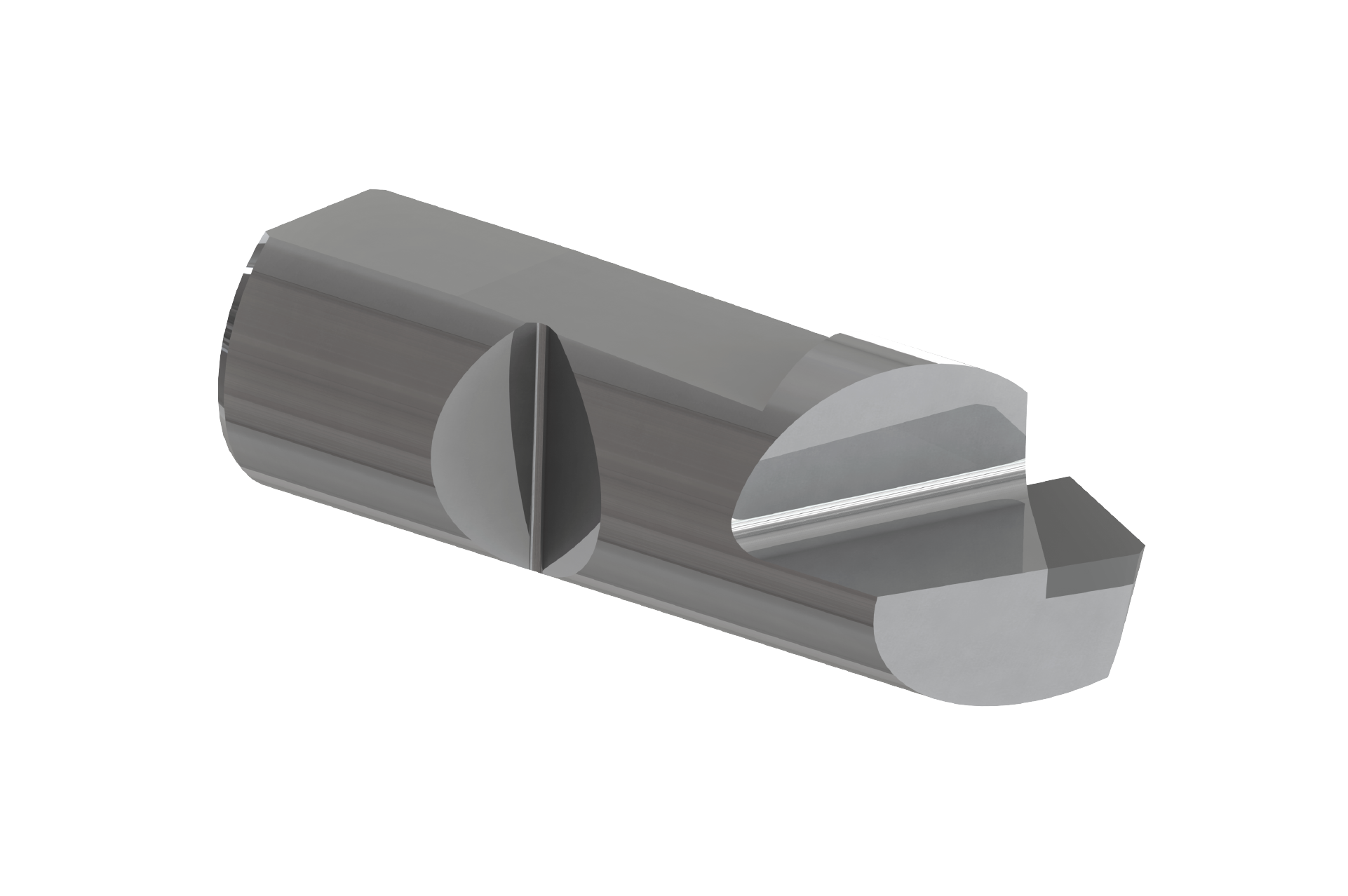

CBN Solid – Shapes

CBN – Insert

CNC – Production

CBN Insert Indonesia PCD Insert Indonesia CBN Tools Indonesia PCD Tools Indonesia CBN Insert Batam PCD Insert Batam CBN Tools Batam PCD Tools Batam CBN Batam PCD Batam CBN Batam PCD Batam PCD CUTTING INSERTS CBN CUTTING INSERTS