NC38 API thread gauge-NC38 Numbered Connections Ring Gage Plug Gage

We are leading supplier of thread gauges. we can supply thread ring gages for external thread and thread plug gages for internal thread. The ring gages are solid, clients can use them directly, no need setting plug gages. The thread plug gages are taperlock, double ends with one handle. All these thread gages include GO NOGO. If clients need left hand thread (LH), please specify specially, we also can supply them. gaugestools is Paypal golden key supplier, we accept Credit card payment (Visa, Mastercard, American express, Discover) through Paypal, Paypal can provide purchase protection for clients.

gaugestools can supply Metric, United Inch( UNEF,UNF, UNC,UN,UNS), Stub ACME, ACME, BSPP (also called G), BSPT (also called R), NPT, Trapezoidal (Tr),MJ, UNJ and whitworth etc thread gauges. If clients need plain thread gages, we also can supply them.

• Metric thread gauges from M1-M150 many sizes in stock,class of fit: ring gage 6g, plug gauge 6H,other tolerance need custom production.Common pitch: 8,6,4,3,2,1.5,1,0.75,0.5. For special pitch, it need custom production. Standard: ISO1502, ASME B1.3M, ASME B1.16M

• UN, UNF, UNS, UNEF thread gages from 0.06″-6″ in stock, class of fit: ring gage 2A, plug gage 2B, other tolerance need custom production.Common TPI: 4,6,8,12,16,20,28,32, For special TPI, it need custom production. Standard: ASME B1.2, ASME B1.3.

• ACME thread gauges from 1/4″-5″ (1/4″-16, 1/2″-10, 5/8″-8, 3/4″-6, 7/8″-6 , 1 1/4-5 etc), Class of fit: 2G,3G,4G. Standard: ASME B1.5. Stub-ACME thread gauges from 0.25″-6.5″ (0.25″-16, 0.5″-10, 0.625″-8, 0.75″-6, 0.875″-6 , 1.25″-5 etc), Class of fit: 2G Standard: ASME B1.8

• BSPP(G),BSPT(R) from 1/8″-6″ in stock( 1/8″, 1/4″, 3/8″, 1/2″, 5/8″, 3/4″, 7/8″, 1″, 1 1/8″, 1 1/4″, 1 1/2″, 1 3/4″, 2″, 2 1/4″, 2 1/2″, 2 3/4″, 3″, 3 1/4″, 3 1/2″, 4″, 6″ all these sizes in stock)

• NPT thread gauges from 1/16″-6″ in stock(1/16″, 1/8″, 1/4″, 3/8″, 1/2″, 3/4″, 1″, 1 1/4″, 1 1/2″, 2″, 2 1/2″, 3″NPT, 3 1/2″, 4″, 5″, 6″ all these sizes in stock) Standard: ASME B1.20.1

• Trapezoidal thread gauges from Tr8-Tr150, class of fit: ring gages 7e, plug gauges 7H Standard: Din103

• BSW/BSF whitworth thread gauges from 3/16″-3″ in stock, standard: BS919-2

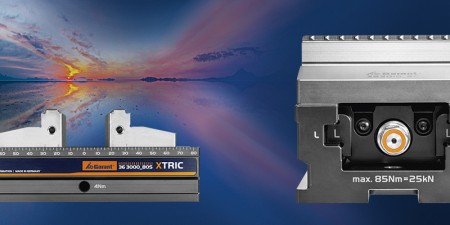

gaugestools has world-class testing equipment, each gage will be strictly checked and confirmed quality. If clients need, we can provide long form calibration certificates from calibration lab ISO17025 accredited.

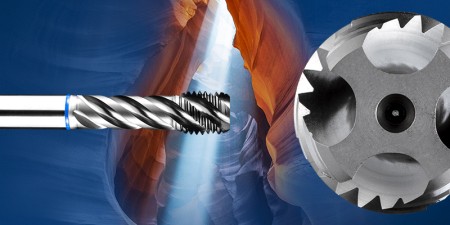

We are also dedicated to supplying outstanding thread taps and dies, including Metric thread taps, UN thread taps etc.

Nowadays, our thread gauges and taps are very popular in Europe, North America etc developed countries. We have been supplying these tools to Parker, ABB , Danfoss, Watts etc famous companies. Customer satisfaction is our pursuit forever. Welcome new and old clients to talk business with us! you can reach us by mail, telephone, Whatsapp etc.