Soda Api

Soda Api bahan kimia ini disebut juga caustic soda yang dapat di gunakan di dalam industri Tambang emas, Agro Indstri, Kimia Industri, Taxtil, etc

Soda Api bahan kimia ini disebut juga caustic soda yang dapat di gunakan di dalam industri Tambang emas, Agro Indstri, Kimia Industri, Taxtil, etc

Kami adalah Distributor Garam Industri sekaligus Supplier Garam Dapur yang Jual Garam Industri maupun rumah tangga. Kami melayani pemesanan dan pengiriman keseluruh wilayah Indonesia. Sebagai Distributor Garam Industri yang berpengalaman kami tidak hanya sekedar jual garam industri namun juga beserta dengan memberikan pelayanan yang optimal, kami juga memberikan penawaran harga murah untuk berbagai produk yang kami sediakan. Garam Industri merupakan garam di digunakan khsusus untuk industri garam ini mempunyai kualifikasi khusus yang berbeda dengan garam dapur yang biasanya di fungsikan untuk kebutuhan rumah tangga.

Dengan pengalaman sebagai Supplier Garam Dapur, kami adalah konsultan yang memahami kebutuhan garam anda. Kami selalu berusaha memenuhi kebutuhan klien dengan menjual garam industri dengan spesifikasi garam yang dapat disesuaikan dengan kebutuhan industri. Untuk kebutuhan garam industri ataupun garam dapur silahkan menghubungi kami.

Keyed chucks are engineered to either loosen or tighten the hold on a tool by using a key. Keyed chucks offer the advantage of applying additional torque on the bit when slippage is a concern during heavy-duty applications.

Keyless chucks are engineered to quickly loosen and tighten a tool on the chuck collar of the drill, either by manual operation or when torque is applied. Rotating the chuck collar in a counterclockwise direction will loosen the tool.

Hybrid drill chucks are engineered with both keyed and keyless systems. The keyless portion automatically tightens, while the keyed portion is adjusted on the chuck to offer added gripping and torque support on the tool.

This Machine is Equipped With Eyshield That Can Protect Your Eyes From Spark or Sparks. There are Lights and Magnifying Functions on One Side of The Eyeshield That Can Help The Grinding Process More Accurately.

With its offices located in California USA, London & Sheffield UK, and Mannheim Germany, Baucor is a globally recognized leading manufacturer and supplier of premium quality standard and custom industrial blades, machine knives, and precision wear parts and tools made from tungsten carbide and steels.

DIAL INSIDE GAUGE MERK PEACOCK TYPE U3HA

Ideal for measuring the internal diameters of relatively large holes and internal wall surfaces.

The shaper is one of the most versatile and important devices used in production and maintenance centers. It is an important production machine along with milling and lathe machines. The primary role of this tool is to produce surfaces that are at different planes. The equipment contains powerful motor that develops the rotary motion. This motion is the changed to reciprocating movement . The reciprocating feed is then connected to the cutting tool such that the cutter moves forward and backwards. During the forward stroke, the specially shaped cutter makes an incision along the workspaces but does not cut on the backstroke. Vertical feed is provided automatically so that the groove made by the cutter continuously deepens to the required depth. During the backward stroke, the vertical position of the cutter changes so that it removes some material during next cycle. The vertical feed and cutting speed are adjusted to match the type of metal, depth of cut and type of operation.

Use of shaping machine in gear manufacturing

Gears are an important constituent in vehicles, machines and other parts. The main types include: bevel, spur, helical and worm gears. The main methods used to manufacture different types of gears include: hobbing, milling, shaping, broaching and grinding. This shaping process has been used for a long time to manufacture them. The blank or a round work piece is mounted on the equipment table. The tool resembling the tooth to be cut is mounted on the tool clamp on the device. The reciprocating motion of the tool forms a single tooth on the round work piece. Once completed, the blank is rotated using an indexing head. The indexing head is set such that it accurately rotates the blank to a position where the next tooth will be formed. This process is used in manufacturing both internal and external components. Shaping machine and broaching are very much similar and are used on very large work pieces that require extra force to manufacture.

For manufacturing plants that require high production runs, cutting of one piece at a time is not convenient. In this case, pinion shaped cutters are used. They are mounted on the shaper while the blank is clamped on the equipment table. As the cutter moves forward and backwards, the whole gear is formed in a single operation. In addition, this equipment is also widely used to form keyhole, slots and internal splines that fasten pulleys on the shaft.

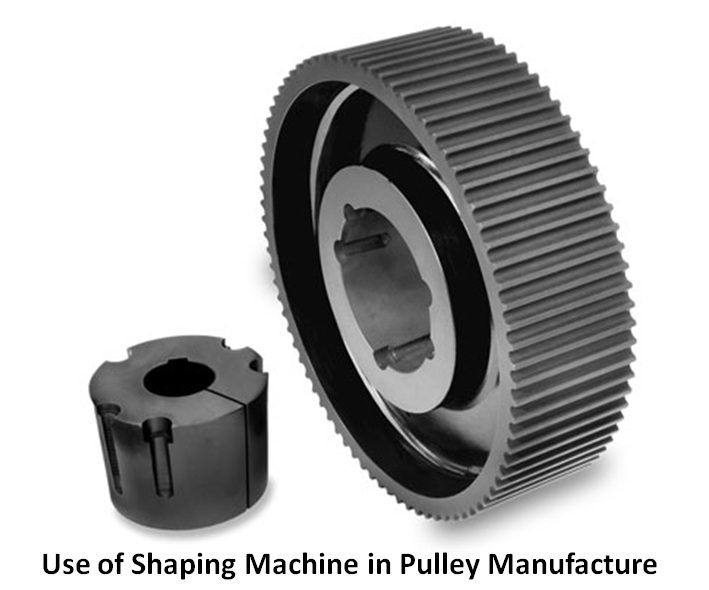

Use in pulley manufacture

Pulleys are used in many industries to transfer rotary motion between different components. The increase or decrease speed depending on the ratio of the diameter of the driver and driven wheels. The shaper is used to produce internal slots and keyways which are used to assemble the pulley wheel on the shaft. The slot is made on the internal radius of the pulley using this device. Therefore, the shaper plays a fundamental role in the development of rotary components.

With the DOT-LEM35 Laser Engraving Machine, Laser engraving, Laser cutting and Laser marking has evolved from a difficult process to an easy task. Just Plug and Go!

Finishing media and compounds are the key to determining the quality of the surface finish.

Careful engineering and selection of the right components unfailingly lead to optimum surface treatment results by perfectly matching material and shape of the product as well as the processing conditions.

A wide range of media is available, including vitrified, sintered and plastic media for wet finishing and specially developed media for dry finishing. Also, a variety of process compounds is available for specific finishing requirements.

Keynote:

Abrasive tools Indonesia, Polishing Tools Indonesia, Abrasive Tools Batam, Polishing Tools Batam, Grinding Disc Indonesia, Grinding Disc Batam, Grinding Wheel Indonesia, Grinding Wheel Batam, Grinding Indonesia, Grinding Batam, Abrasive Cloth Indonesia, Abrasive Cloth Batam, Buffing Wheel Indonesia, Buffing Wheel Batam, Compounds Indonesia, Compounds Batam.

Hand Tap / Tapping tools and Dies are tools used to create screw threads, which is called threading.

Honsberg Bimetal Band Saw Blade SECURA 700724. SECURA 700724 bimetal band saw blade made of ~4% high chrome alloyed backing material and HSS cutting edge made of HSS M42 (material No.1.3247) with cobalt content. The theeth hardness is 68HRc. Suitable for dual column, horizontal and vertical band saw machines.

Band Saw Hosberg, Band Saw Indonesia, Band Saw Batam

Röntgen supplies high-quality saw blades for your cutting application. Reliable and cost-efficient performance on your sawing machine is guaranteed. Come and experience our service and the quality of our products. Explore our websites for your initial information or contact us directly.

Band Saw Blade Indonesia, Band Saw Blade Batam, Band Saw Batam, Band Saw Indonesia

Yamamoto test blocks are reference materials, standardized to determine the average hardness of the block surface. The resulting certified value provides a reference number and tolerance that should be met during hardness tester verification to ensure compliance with performance standards.

Yamamoto test blocks are calibrated in accordance with ASTM E18-00 section C using Rockwell HRC standard reference materials.