Description

The number of laser cleaning applications is growing exponentially. Every day new possibilities are discovered and explored. From the classical rust removal to the restoration of natural stone building facades. And everything in between: paint removal, de-coating, mold cleaning, de-oiling, special

surface treatment and even labeling and marking. The industrial applications P-Laser products are used for vary from the most inaccessible tiny area to vast surfaces of public or private infrastructure. Always delivering results above expectations.

SURFACE CLEANING

Industrial surface cleaning is probably the best known laser treatment application. Rust and paint removal, degreasing, activation, restoration, etc. are all considered as surface cleaning applications.

MOULD CLEANING

As they leave no blast media residue or disposal, both our Low and High Power laser equipment are the optimal solution for cleaning moulds used for rubber, plastic, glass and composite products.

WELD CLEANING

Weld cleaning is definitely one of those classic applications of industrial laser cleaning.

It can be applied on steel, stainless steel and aluminium welds without damaging the substrate.

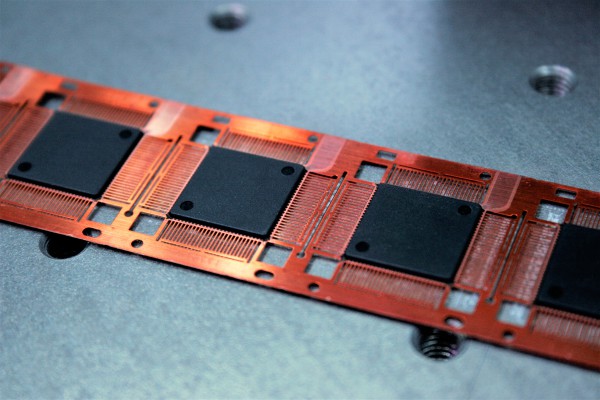

MARKING

Did you know that the working principle of marking or labeling is exactly the same as for laser cleaning?

P-Laser’s Low Power systems are ideal for all your marking applications.