Description

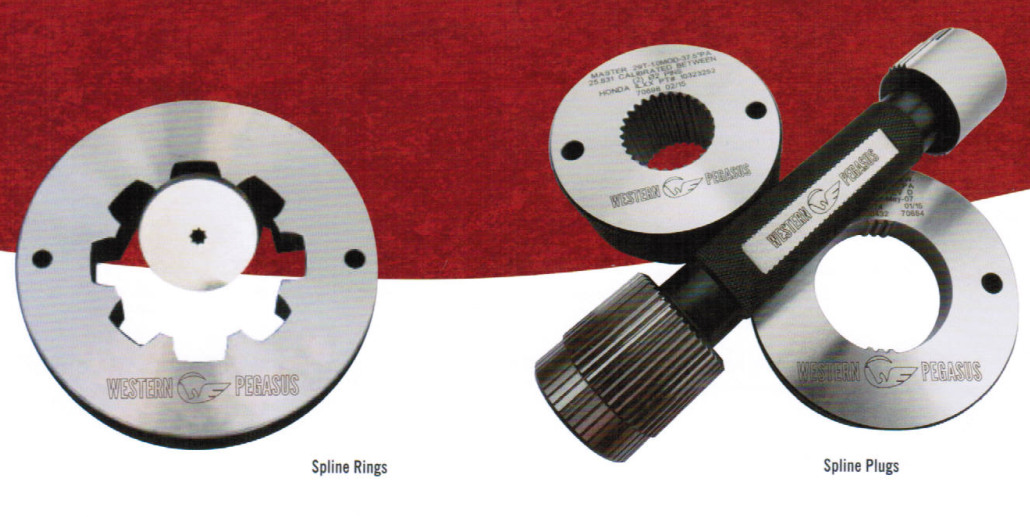

Spline Plugs & Rings Gauge

We offers a full line of spline ring and plug gauges. Spline ring and plug gauges provide the most basic and simple inspection of spline components.

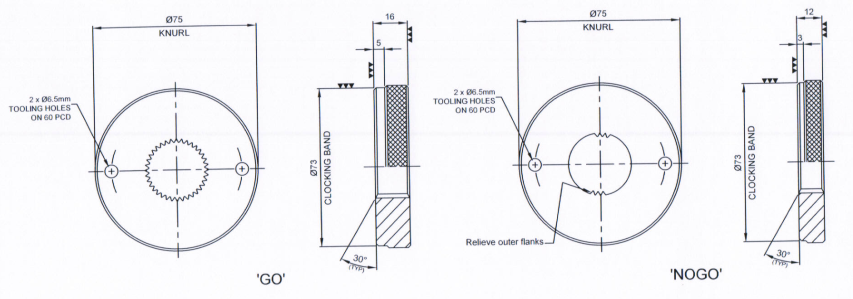

![]() Go Composite Ring Gauges provide a basic check of the maximum effective tooth thickness of an external spline component.

Go Composite Ring Gauges provide a basic check of the maximum effective tooth thickness of an external spline component.

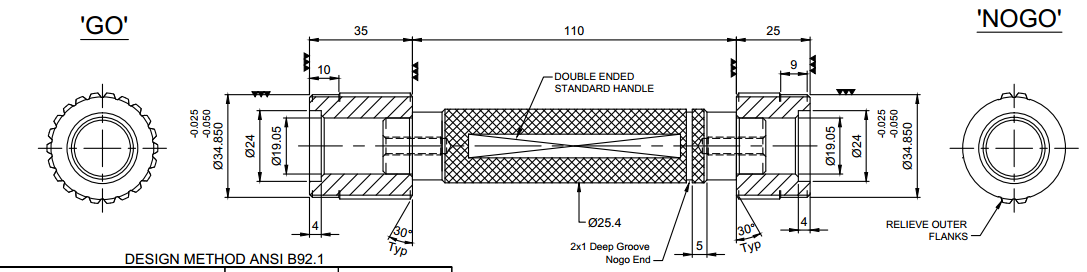

![]() Go Composite Plug Gauges provide a basic check of the minimum effective space width of an internal spline component.

Go Composite Plug Gauges provide a basic check of the minimum effective space width of an internal spline component.

![]() NoGo Sector Ring Gauges provide a basic check of the minimum actual tooth thickness of an external spline component.

NoGo Sector Ring Gauges provide a basic check of the minimum actual tooth thickness of an external spline component.

![]() NoGo Sector Plug Gauges provide a basic check of the maximum actual space width of an internal spline component.

NoGo Sector Plug Gauges provide a basic check of the maximum actual space width of an internal spline component.

![]() NoGo Composite Ring Gauges provide a basic check of the minimum effective tooth thickness of an external spline component.

NoGo Composite Ring Gauges provide a basic check of the minimum effective tooth thickness of an external spline component.

![]() NoGo Composite Plug Gauges provide a basic check of the maximum effective space width of an internal spline component.

NoGo Composite Plug Gauges provide a basic check of the maximum effective space width of an internal spline component.

Spline rings and plug gauges can also be designed and built for the combined inspection of major or minor diameter fit components. Other elements in the design of a gauge can include locating features such as journal diameters, ground bores, flats and holes in relation to a tooth or space to aid alignment.