Description

Preventive Maintenance

Performing regularly scheduled preventative maintenance (PM) services on the components of your compressed air system is vital to insuring your system performs at its optimum level, keeping warranties in effect, maintaining equipment reliability, and producing the greatest return on your investment over the long run. Neglecting routine PM services increases your risk of costly breakdowns and shortens the life expectancy of your compressed air equipment.

To help our customers stay on top of their PM requirements, Air Compressor Service developed a proprietary data base system that tracks all maintenance and repair services we perform on your compressed air equipment and projects PM dates based upon periodic hour readings and/or dates of the last service and manufacturers’ recommended PM schedules. As the date of your service nears, we will call you to confirm that you are ready to have the PM services performed. We will then assure that the required parts are on hand and call you again to schedule a date for the service. Our customers never have to worry about remembering to have their systems serviced. We take care of that for you.

Another important aspect of our preventative maintenance services in our free oil analysis program. We periodically test oil using an instant results total acid number (T.A.N.) test or take an oil sample and send it to a laboratory for spectrographic analysis. Spectrographic analysis will confirm whether your oil is suitable for continued use, detect signs of unusual internal wear, and help maintain some warranties.

Repairs and Overhauls

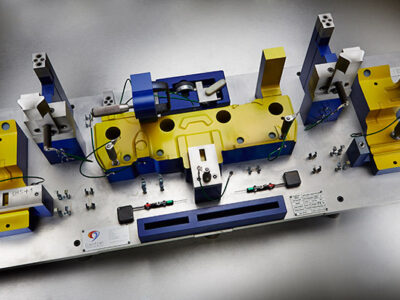

Air Compressor Service repairs and overhauls most major brands of industrial air compressors from 5 through 300-horsepower. One of our experienced service technicians will examine your air compressor to determine the cause of its malfunction, order parts and perform the repairs on-site or in our shop, whatever is most appropriate for the circumstances.

If your industrial air compressor needs overhauling, we will quote you the cost and time required to complete a standard overhaul, with the proviso that disassembly of the compressor may reveal other internal parts that require replacement too. In any case you will be kept apprised of the situation and asked to approve additional recommended repairs.

Emergency Repairs

Even with the best preventative maintenance program compressed air equipment does occasionally break down, usually at the worst possible time, it seems. We understand that breakdowns can be expensive in terms of lost production and idle workers. Therefore, we make every effort to respond rapidly to your emergency breakdown.

If you have an after-hours emergency breakdown, call us, listen to the prompts and select our emergency voice mailbox. Record your name, your company name, a phone number where you can be reached, and a description of your problem as best as you know it.

Our phone system will alert one of our technicians that there is a message in the emergency voice mailbox. He will retrieve it, contact you and arrange to have a service technician respond to your emergency. Of course, overtime rates apply for after-hours and weekend work.