Description

Cast Iron Reference

In general, emission spectrometers and X-ray fluorescence analysis devices are widely used in plants producing cast iron and various types of alloys. The users of these devices need calibration specimens to confirm the stability of the devices.

JFE-TEC has established methods to manufacture calibration specimens for use for such instrumental analysis through experiments and research over many years. Our original calibration specimens feature extremely low segregation within specimens and fine homogeneity of metallic structure.

Product Types and Compositions

| Product type | Details | Available components |

|---|---|---|

| Cast iron | Gray cast iron, alloy cast iron, ductile cast iron, stainless cast iron, etc. | C / Si / Mn / P / S / Cu/ Ni / Cr / Mo / V / Pb / Ti / Sn / B / Sb / Zn / Ce / Ca / Bi / Al / Mg |

| Alloy | Low-alloy steel, stainless steel, nickel alloys, copper alloys, etc. | Cu / Ni / Cr / Mo / Fe /C / Si / Mn / P / S / Sn / Sb / Pb / Zn / Al / Ta / Nb / Co / Mg / Ca / Ti /B / V / W |

* Specimens containing other elements can be manufactured by request.

Specimens for analysis of O, N, and H in steel

| Specimen form and size | 0.5 or 1.0 g pins or balls 50 or 100 g per bottle |

| Specimen No. | O | N | H |

|---|---|---|---|

| JSMM 401 | 7 | 55 | – |

| JSMM 402 | 180 | 130 | – |

| JSMM 403 | 1200 | – | – |

| JSMM 481 | – | – | 0.7 |

Note: The exact content varies by lot.

Specimens for analysis of C and S in steel

Specimen form and size: Fine grains, 150 g per bottle

| Specimen No. | C | S |

|---|---|---|

| JSMM 451-1 | 0.93 | 0.0096 |

| JSMM 452-1 | 2.78 | 0.011 |

| JSMM 453-1 | 3.2 | 0.0136 |

| JSMM 454-1 | 3.73 | 0.0298 |

For Gas Component Analysis

JFE-TEC sells specimens for use for analysis of gas components (C, S, O, N, and H) in steel.

Specimens for use for O, N, and H analysis are produced in pin or ball shape with a weight of 0.5 g or 1.0 g, and those for C and S analysis are processed into fine grains. These specimens completely eliminate the need for troublesome pretreatment such as cutting, polishing, and washing. This reduces variation in analytical results due to personal differences in the way pretreatment is performed and enables quick, accurate confirmation of the performance of analysis equipment.

Specimens for analysis of O, N, and H in steel

| Specimen form and size | 0.5 or 1.0 g pins or balls 50 or 100 g per bottle |

| Specimen No. | O | N | H |

|---|---|---|---|

| JSMM 401 | 7 | 55 | – |

| JSMM 402 | 180 | 130 | – |

| JSMM 403 | 1200 | – | – |

| JSMM 481 | – | – | 0.7 |

Note: The exact content varies by lot.

Specimens for analysis of C and S in steel

Specimen form and size: Fine grains, 150 g per bottle

| Specimen No. | C | S |

|---|---|---|

| JSMM 451-1 | 0.93 | 0.0096 |

| JSMM 452-1 | 2.78 | 0.011 |

| JSMM 453-1 | 3.2 | 0.0136 |

| JSMM 454-1 | 3.73 | 0.0298 |

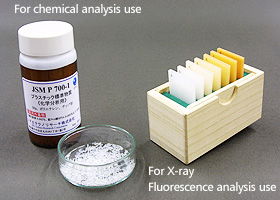

Plastic Original Standard Reference Materials

Utilizing our technologies for manufacturing iron and steel-related standard reference materials, we sell plastic standard reference materials containing various added components for application to chemical analysis and instrumental analysis.

Specimens suitable for analysis to ensure compliance with the EU’s RoHS Directive are also available.

Material: Polyethylene

For Chemical Analysis

For hazardous component analysis [for compliance with RoHS Directive]

Specimen form and size: Grains, 50 g per bottle

| Specimen No. | Cd | Pb | Hg | Cr | As | Br | Cl | S |

|---|---|---|---|---|---|---|---|---|

| Unit | (μg/g) | (%) | ||||||

| JSM P 700-1 | 5.0 | 5.0 | 5.3 | 4.9 | 9.1 | 0.002* | 0.004* | 0.006* |

| JSM P 701-1 | 113.5 | 111.3 | 111.6 | 114.8 | 187.3 | 0.05* | 0.06* | 0.04* |

*: Reference value

Specimen form and size: Grains, 50 g per bottle

| Specimen No. | F | Na | Mg | Al | Si | P | S | Ca |

|---|---|---|---|---|---|---|---|---|

| JSM P 702-1 | – | 0.0012 | 0.0015 | 0.0012 | 0.0008* | 0.0011 | 0.0014* | 0.0013 |

| JSM P 703-1 | 0.018* | 0.024 | 0.029 | 0.022 | 0.018 | 0.017 | 0.021* | 0.023 |

| Specimen No. | Ti | Zn | Fe | Cl | Cr | |||

| JSM P 702-1 | 0.0009 | 0.0010 | 0.0015 | 0.0017* | 0.0012 | |||

| JSM P 703-1 | 0.017 | 0.020 | 0.021 | 0.018* | 0.020 |

*: Reference value

For X-ray Fluorescence Analysis

For hazardous component analysis [for compliance with RoHS Directive]

Specimen form and size: Sheet (30 × 30 mm, 3 mm [T]), a set of 7 levels

| Specimen No. | Cd | Pb | Hg | Cr | As | Br |

|---|---|---|---|---|---|---|

| Unit | (μg/g) | (%) | ||||

| JSM P 710-1 (a – g) | <1 – 1.11×103 | <1 – 1.12×103 | <1 – 1.09×103 | <1 – 1.10×103 | <1 – 1.95×103 | <0.001 – 0.62* |

* : Reference value

Your instrument may, depending on its performance, be affected by coexisting elements and may not be able to measure accurately. Guidelines for applicability (Before measurement, please confirm charts and the linearity of the calibration curve of the instrument to be used.)

| Cd | Pb | Hg | Cr | As | Br | |

|---|---|---|---|---|---|---|

| Wavelength dispersive X-ray fluorescence spectrometer | – | – | – | – | – | * |

| Energy dispersive X-ray fluorescence spectrometer | – | – | – | N/A | N/A | * |

-:Applicable N/A:Not applicable *:Please inquire

For antimony and tin analysis

Specimen form and size: 40 mm (D) × 4 mm (T), a set of 4 levels

| Specimen No. | Sb(%) | Sn(%) |

|---|---|---|

| JSM P711-1 (a – d) | < 0.001 – 0.079 | – |

| JSM P712-1 (a – d) | – | < 0.001 – 0.101 |

Nickel Ore Original Standard Reference Materials

Specimen form and size: Powder, 50 g per bottle

| Specimen No. | T.Ni | T.Co | T.Fe | MgO | CaO | SiO2 | T.Cr | Al2O3 |

|---|---|---|---|---|---|---|---|---|

| JSM O800-1 | 2.27 | 0.053 | 14.2 | 26.2 | 0.030 | 35.7 | 0.70 | 0.98 |

| JSM O800-2 | 2.07 | 0.036 | 11.5 | 23.3 | 0.37 | 45.4 | 0.57 | 1.27 |

| JSM O800-3 | 1.90 | 0.072 | 15.0 | 26.1 | 0.034 | 34.9 | 0.84 | 0.84 |